Oil and water treatment techniques

Operators face a number of issues when designing and operating surface facilities for gathering and processing of produced oil and formation water and also when treating oil to stock tank conditions due to physical and chemical properties of produced fluids, different field development stages, recovery mechanisms, lifting methods, and potential hazardous factors (presence of FeS, H2S, combined processing of commingled oil and the like). Successful solutions to such problems call for an integrated approach tailored to specific needs of each customer

Ufa Scientific and Technical Center offers such integrated approach with overall support from the beginning to the end including the following stages (turn-key basis):

- Operational Analysis of Oil Gathering and Transportation System

- Operational Analysis of Preliminary Water Discharge Units (Free Water Knockout)

- Operational Analysis of Oil Processing Facilities

- Operational Analysis of Water Treatment Facilities

- Engineering, Design (Author) Field Supervision and Audit

Ufa Scientific and Technical Center delivers equipment for formation water treatment in compliance with OST 39-225-88 and provides services for installation support and supervision with follow-up commissioning and process stabilization

Coalescing elements are employed for water cleaning which use oil-repellent materials and a variable profile for effective consolidation of oil droplets and precipitation of solids and impurities without any resistance to the movement of the main flow

Functional principle

- As the liquid flows through the corrugated plates it segregates into layers thus intensifying the separation process

- The direction of the liquid flow changes many times as it goes through the plates forming zones of effective coalescence and discharge of consolidated oil droplets with simultaneous precipitation of solids and impurities

- Oil-repellent materials used for manufacturing coalescing elements secure the self-purification effect and thus longer lifespan (higher endurance)

- The quality of operation is ensured by high level of process automation

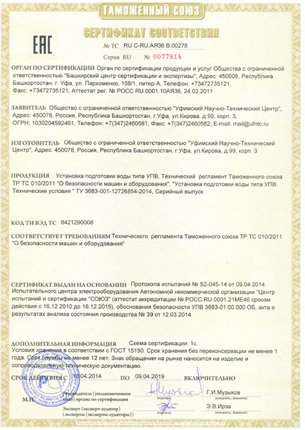

Our sertificates

+7 347 2460582

+7 347 2460582